Inspection Conveyor.

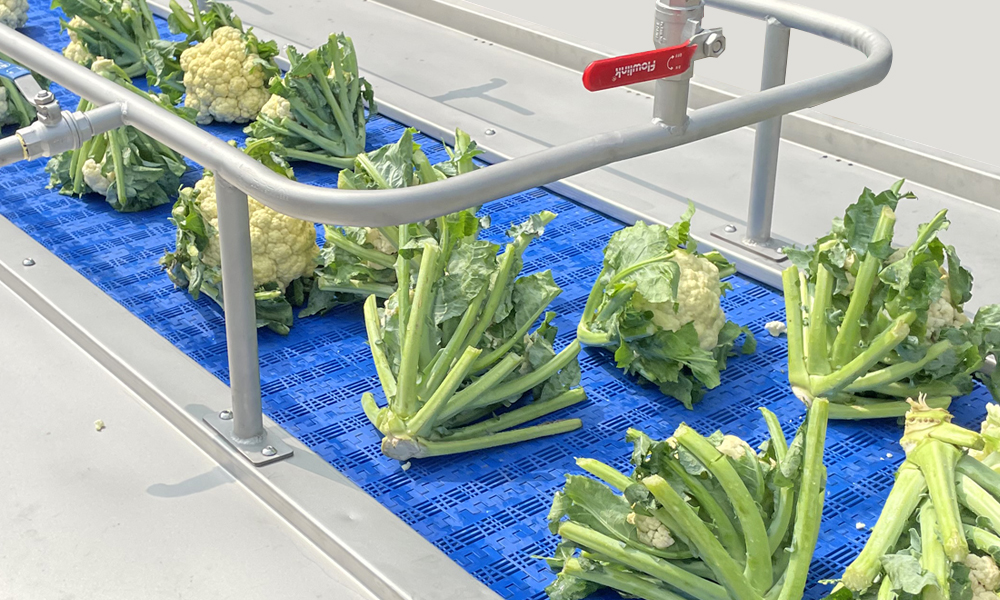

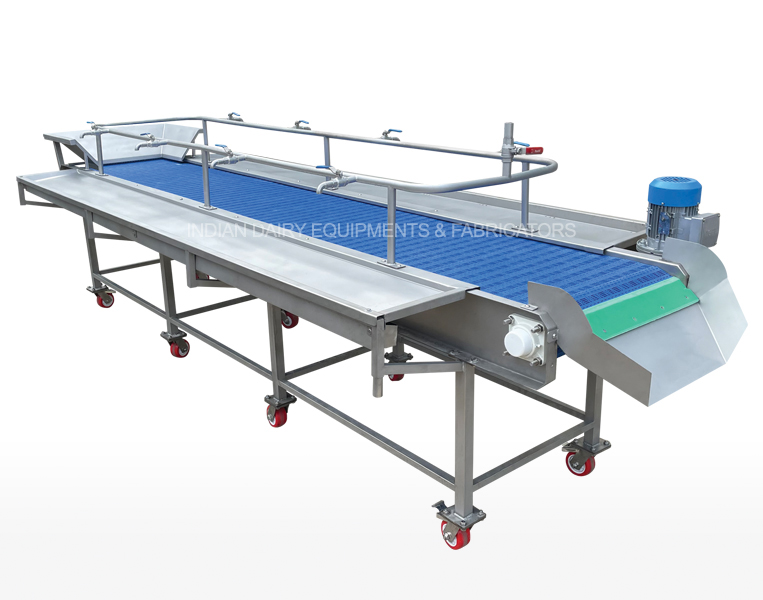

An IDEF Inspection Conveyor is designed for the transportation and inspection of products.

Generally used as part of the continuous processing of food plants. The product is fed on the belt of the conveyor where it is divided into different lanes for inspection. IDEF presents an excellent quality Inspection Conveyor. The provided conveyor is manufactured using premium quality material and the latest techniques. The offered conveyor is examined on a set quality parameter to deliver a better range to the clients.

- Adjustable height and speed and easy to operate.

- PP support sheet on which the belt runs along the length of the conveyor.

- Drive arrangement consists of geared motors, bearings, tensioning arrangement, etc.

- We can make the machine based on the customer’s request.